Demand Driven MRP:

The Proven, Quiet Way to Keep Your Supply Chain Running Smoothly Without Drawing Attention

Supply chain silence is a beautiful thing.

The best Supply Chains are the ones you never notice. When everything is running perfectly, products arrive on time, shelves are full, and customers are satisfied - all with the drama.

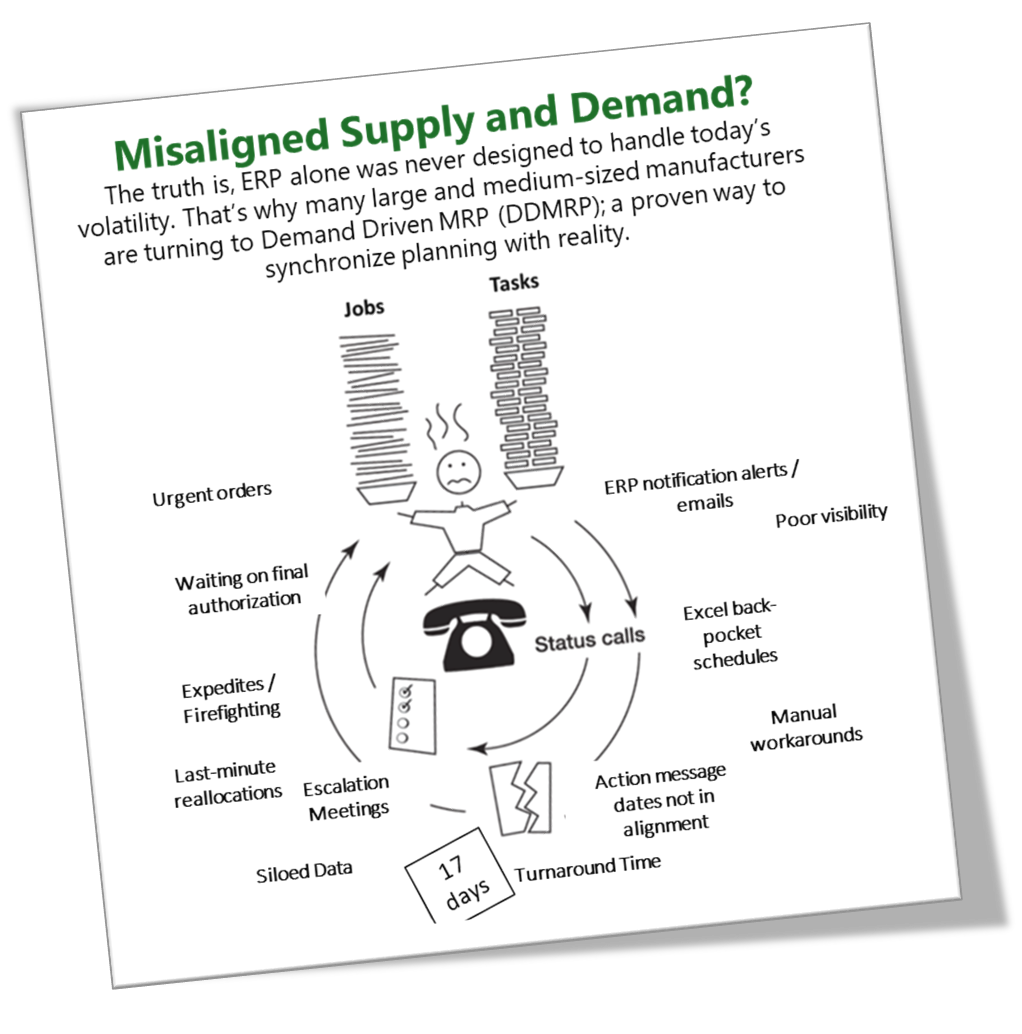

Here are three signs your system is working against you, not for you:

1. 𝗣𝗹𝗮𝗻𝗻𝗲𝗿𝘀 𝘄𝗼𝗿𝗸 𝗮𝗿𝗼𝘂𝗻𝗱 𝘁𝗵𝗲 𝘀𝘆𝘀𝘁𝗲𝗺 𝗶𝗻𝘀𝘁𝗲𝗮𝗱 𝗼𝗳 𝘄𝗶𝘁𝗵in 𝗶𝘁

If your team relies on shadow Excel spreadsheets, back-pocket schedules, manual adjustments, or gut feel, even after a technology investment, that’s not “customization.” It’s a red flag.

2. 𝗙𝗼𝗿𝗲𝗰𝗮𝘀𝘁𝘀 𝗱𝗼𝗺𝗶𝗻𝗮𝘁𝗲 𝗲𝘃𝗲𝗿𝘆 𝗰𝗼𝗻𝘃𝗲𝗿𝘀𝗮𝘁𝗶𝗼𝗻

If every meeting starts and ends with a debate about forecast accuracy, you’re stuck in reactive mode. That’s not planning, it’s defending.

3. 𝗘𝗮𝗰𝗵 𝗳𝘂𝗻𝗰𝘁𝗶𝗼𝗻 𝗼𝗽𝘁𝗶𝗺𝗶z𝗲𝘀 𝗹𝗼𝗰𝗮𝗹𝗹𝘆

If supply, demand, manufacturing, and finance all have different plans, you’ll always be making compromises and trade-offs instead of driving performance.

When things go sideways in your supply chain,

what usually happens next?

trouble is, most supply chains are driven with inaccurate forecasts

with lots of backorder alerts and capacity sapping averting expedites.

In traditional forecast driven MRP planning, failure is expected.

Forecast misses.

Fire drills.

Expedites.

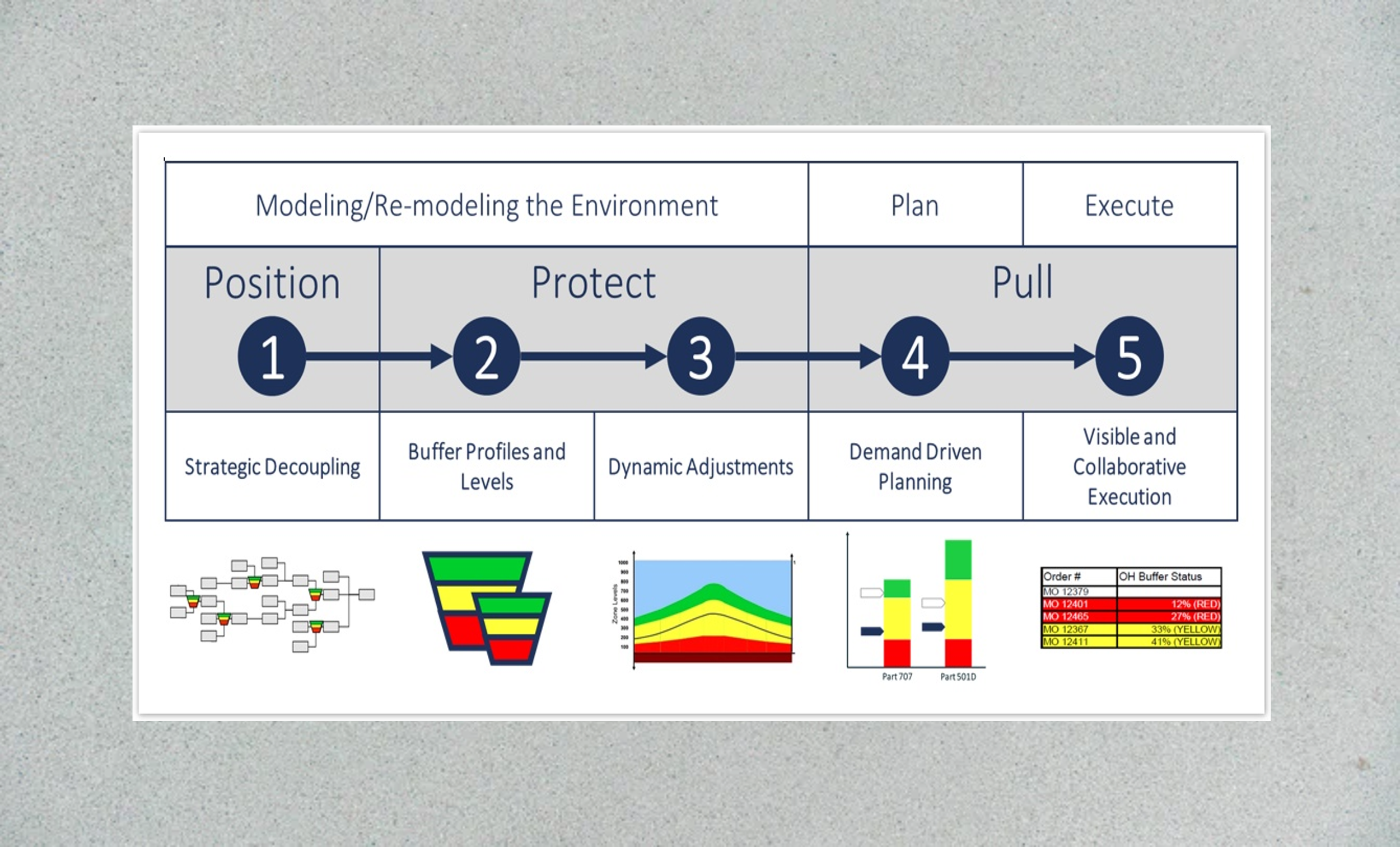

Demand Driven MRP flips that. You buffer against chaos.

You plan for reality. You plan with a tool built to firewall your business from variability, change and uncertainty.

And you stop apologizing.

Efficient, invisible and excellent supply chains are decoupled and demand driven.

Unlock the power of a demand-driven supply chain with Synchronata Solutions. We transform operations from reactive to proactive, aligning inventory, production, and distribution with real-time demand signals. Our tailored implementation is designed to enhance agility, reduce waste, and build resilience, turning supply chain challenges into competitive advantages. Partner with us to optimize flow and drive sustainable growth.

We provide the right mix of planning, technical expertise, specialized tools and ongoing engagement to bridge the gap between strategy and design, and ensure that your supply chain reaches its full, unconstrained potential.

You need a supply chain that’s resilient, responsive to complex consumer demands, and differentially enabled—all while remaining efficient and affordable.

DDMRP: The Proven, Quiet Way to Keep Your Supply Chain Running Smoothly Without Drawing Attention

-

Demand Driven MRP Certification Courses

Ever notice that in supply chain, the only time people notice you is when something goes wrong?

The forecast misses, the supplier delays, the plan breaks… and suddenly, you’re in the fire.

DDMRP is a way out. Not to shine—but to not burn. It’s built for planners and ops teams who want to stop explaining failure and start managing reality.

Quiet, predictable, buffer-driven stability.

No fireworks. No meetings. Just fewer emergencies.

Want to see how others are using DDMRP to disappear from the drama?

-

Demand Driven Supply Chain Planning & Execution

Demand-Driven Supply Chains:

Balancing Resilience and ProfitabilityRecent supply chain disruptions have pushed many leaders toward a "just-in-case" mindset, stockpiling inventory to avoid stockouts. However, high inventory costs can strain profitability without guaranteeing customer needs are met. A demand-driven supply chain offers a smarter alternative—responsive, lean, and customer-focused.

What Is a Demand-Driven Supply Chain?

Unlike traditional forecast-driven models, a demand-driven supply chain uses real customer orders to trigger production and inventory replenishment across all stages—warehouses, factories, and suppliers. Forecasts inform capacity planning (e.g., plants, resources), reviewed monthly via Sales & Operations Planning (S&OP). Execution (S&OE) relies on actual orders, enabling agility and efficiency through responsive, adaptive decoupling buffers.

-

Demand Driven Coaching and Support

Coaching and Support for DDMRP Success

Transitioning to a demand-driven model requires education, expertise and cultural change. Professional coaching and support accelerates adoption:

Training: Equip teams with DDMRP certification (e.g., Demand Driven Institute programs) to master buffer sizing, demand signals, and execution.

Consulting: Engage experts to design tailored S&OP/S&OE processes and optimize buffer parameters (e.g., ADU, lead time, variability factors).

Change Management: Coaches guide leadership and staff to embrace collaboration, shift from forecast reliance, and adopt lean practices.

Ongoing Support: Regular audits and hands-on coaching ensure the effective adoption and maturity of your team in demand driven methodologies and tools.